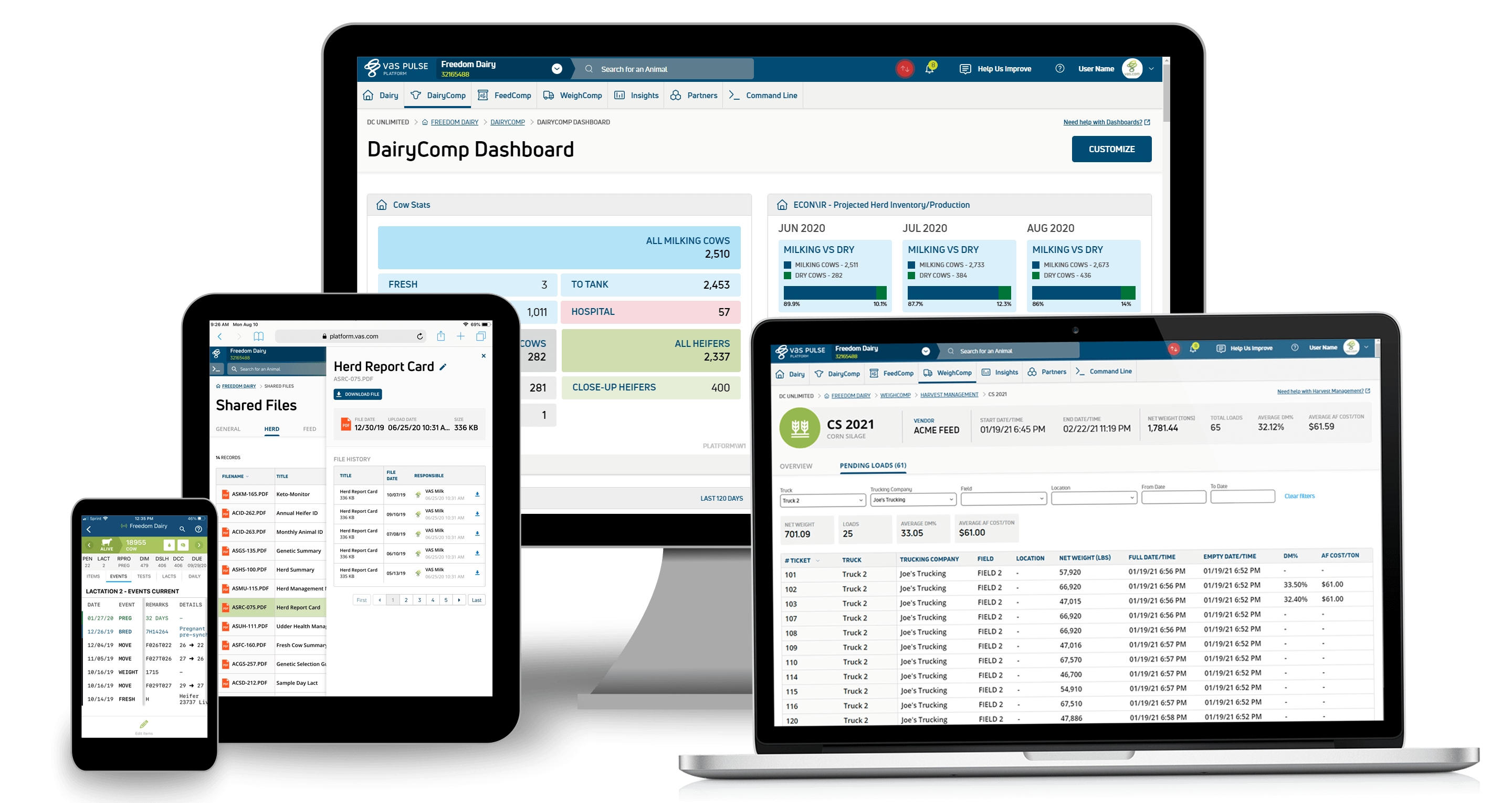

Anytime, anywhere from any device.

around your rotary parlor.

industry leading insights.

VAS is the industry-standard in

connected farm management systems

for data driven dairies

Your farm's data has a story to tell

VAS PULSE

PLATFORM CAN TELL IT

Cloud-based Anytime, anywhere, any device.

Comprehensive, end-to-end products

that span your dairy

DairyComp

Maximizing herd performance starts with

DairyComp.

• Data-driven – explore herd data on micro and macro levels

• Customizable – create reports that make sense to you

• Scalable – small herd or large, there’s a DairyComp for you

Feed

VAS Feed ensures your most expensive

input isn’t a mystery.

• Traceable – gain visibility into inventory, shrink and loss

• Accountable – unite your entire team to work towards common goals

• Accurate – optimize pen feeding with always accurate counts from DairyComp

Integrated with over 50 world-renowned industry partners

See why top clients

CHOOSE VAS

At VAS, we connect farmers to their data through herd and feed management software solutions. We empower them to make the best management decisions with reliable, accurate data at their fingertips.

Your data

Delivered

- Wherever you want it.

- Whenever you need it.

- Whoever needs it.